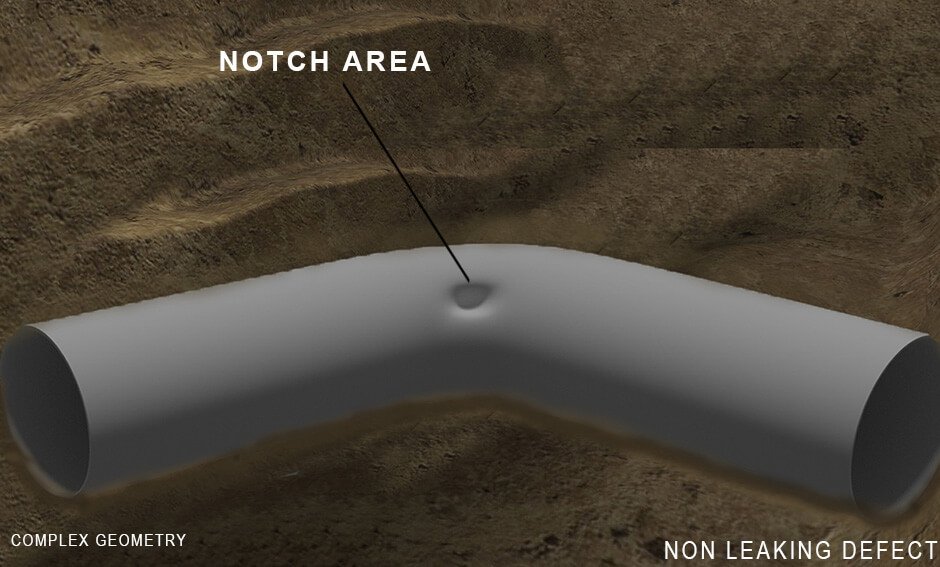

PRODUCT: VR - 301

Tailor-fit wet-lay system to work with unique and complex pipe geometries like bends, T-shape joints and other odd shapes which are challenging otherwise, providing high strength and high pressure bearing capability. Ideal for pipelines having complex structure and difficult to reach workplace.

Tailor-fit wet-lay system to work with unique and complex pipe geometries like bends, T-shape joints and other odd shapes which are challenging otherwise, providing high strength and high pressure bearing capability. Ideal for pipelines having complex structure and difficult to reach workplace.

| Title | Info |

|---|---|

| Layer Thickness (6 layers) | 3.5 mm |

| Tensile Modulus (Circumferential) | 11.32 GPa |

| Tensile Modulus (Axial) | 11.28 GPa |

| Tensile Strength (Circumferential) | 232 MPa |

| Tensile Strength(Axial) | 230 MPa |

| Poisson’s Ratio (Circumferential) | 0.30 |

| Poisson’s Ratio (Axial) | 0.28 |

| Service Temperature Range | -30 C to 150 C |

| Lap Shear Strength to steel | 9.81 MPa |

| Barcol/Shore Hardness | 52.30 shore D |

| Title | Info |

|---|---|

| ½’ to 48’ In-Situ Repair Leaking Defect Pipe Size | Up to 25 mm dia |

| ½’ to 48’ Ex-Situ Repair Leaking Defect Pipe Size | Any size |

| ½’ to 48’ Part wall Loss Pipe Operating Pressure | 350 bars |

| ½’ to 48’ Through wall defect Pipe Operating Pressure | 70 bars |

Related Case Studies

Subscribe now

We will not spam your email.